- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

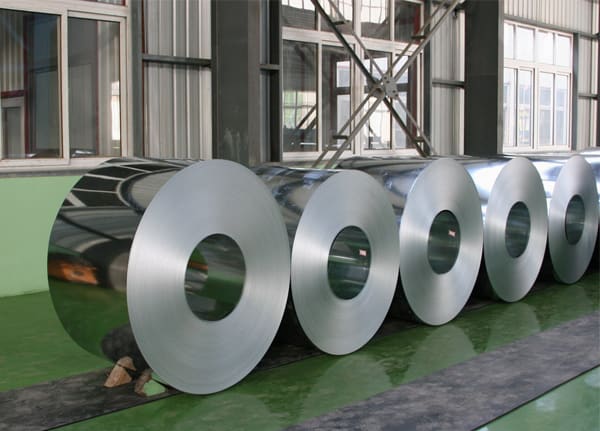

Aluzinc Coil is a high-performance steel product coated with an alloy of aluminum and zinc. It combines the corrosion resistance of aluminum with the sacrificial protection of zinc. This unique composition makes it highly durable and ideal for applications in construction, roofing, and exterior cladding. Aluzinc Coil is available in various thicknesses and finishes, tailored for industrial and architectural projects.

Aluzinc Coil offers several advantages over traditional galvanized steel, including:

Aluzinc Coil finds its use in multiple industries due to its excellent protective properties:

To understand why Aluzinc Coil is preferred over galvanized steel, consider the following comparison:

| Feature | Aluzinc Coil | Galvanized Steel |

| Corrosion Resistance | High | Moderate |

| Reflectivity | High | Low |

| Durability | Long-term | Medium-term |

| Weight | Light | Slightly Heavier |

One of the reasons Aluzinc Coil is popular in construction is its low maintenance requirement. The aluminum-zinc coating prevents rust, even in coastal and industrial areas. Typical maintenance includes periodic cleaning to remove debris or corrosive residues. With proper installation, Aluzinc Coil can last 20-30 years or more, making it a cost-effective choice over the long term.

Selecting the proper Aluzinc Coil depends on application, thickness, and coating type:

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...