Summary:

The thickness of the color-coated coil coating should choose the front coating ≥20μm to effectively prevent the intrusi...

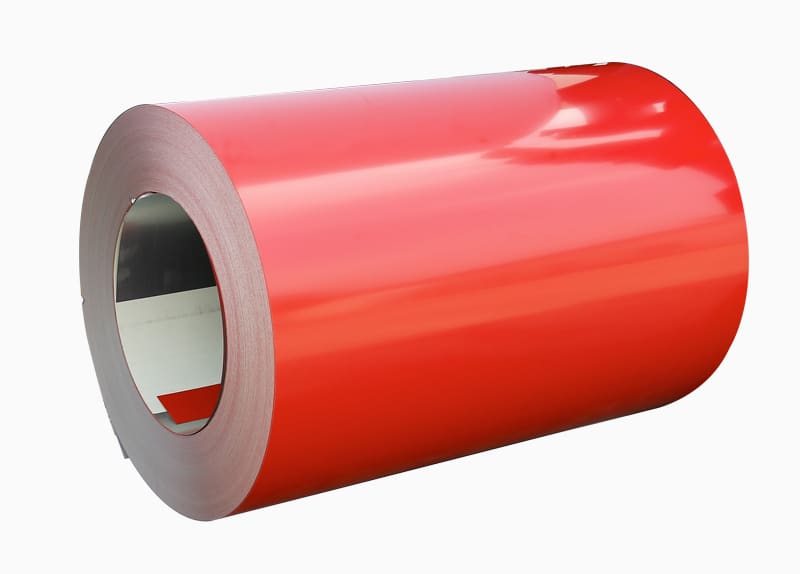

The thickness of the color-coated coil coating should choose the front coating ≥20μm to effectively prevent the intrusion of corrosive media. Because the anti-corrosion mechanism of the primer and the topcoat are different, the primer (≥5μm) and the topcoat (≥15μm) are required respectively. Thickness. Only in this way can the corrosion resistance of different parts of the color-coated roll be balanced.

Color-coated roll coating gloss, high gloss surface dazzling, high reflectivity to sunlight during the day will cause light pollution. The high-gloss surface has a low coefficient of friction and is easy to slip, which can easily bring safety hazards during roof construction.

The aging of color-coated rolls when used outdoors is the first sign of loss of gloss. If repairs are required, it is easy to distinguish between the old and new steel plates, resulting in poor appearance; if the back paint is high-gloss, it is easy to produce halos when there are lights in the room and cause personnel Visual fatigue.

Under normal circumstances, color-coated rolls for construction use medium and low gloss (30-40 degrees).