- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

Most people in the market believe that there are two complete descriptions of color-coated plates, color steel plates, color-coated coils, and color-coated steel coils: one is the thickness, and the other is the color, such as 0.5MM white and gray. The other things seem to be unimportant. In fact, a complete expression of a color-coated product should be described from five major aspects; substrate mechanical properties (yield strength, tensile strength, elongation), coating properties (coating type, coating adhesion, coating yield), coating Performance (film thickness, T-bend, impact, pencil hardness, chalking resistance, salt spray resistance, durability, etc.), surface quality (defects, gloss, color, coating fineness, etc.), surface quality (defects, gloss , Color, coating fineness, etc.), other properties (plate type, dimensional accuracy, tolerance, etc.). Different groups of people (architects, owners, processors, etc.) have different perceptions of this. From the point of view of the production and use of pre-painted steel, the important performance of pre-painted steel is its durability! (Long-term non-chalking, no change in color, no rust performance)

Precautions for installation of roof slab

Repair the wrong place due to self-tapping screws in time.

Holes should be cut according to the actual size when opening the plate. If there is no wrap angle at the opening, a scissors gun or manual scissors should be used to make the hole. The toothless saw should not be used for cutting, because the toothless saw cuts the burrs or Feijian is prone to rust spots. After opening the holes, use the same color paint as the board to prevent corrosion.

Clean up the dirt on the board in time during the installation process.

1.1 Quality control of roof floor installation

(1) Installation quality requirements:

When installing the galvanized steel bottom plate, attention should be paid to the flatness of the bottom of the plate, and there should be no warping deformation in the plate.

The steel bottom plate overlaps a wave crest in the transverse direction. If the bottom plate is not in tight contact with each other and there is a large gap, use Φ5 aluminum pull studs to properly fasten it.

The anchoring is reliable, the installation is smooth, the board seam contact is tight, and the board surface is clean.

(2) Installation quality control:

When the first plate is installed, install it according to the measured control line. When installing the plate, check the straightness of the two ends and the middle of the plate and the parallelism of the overall plate at any time to prevent the entire plate from appearing in a fan shape.

Before installing the plate, mark the fixing position of self-tapping bolts with a marker on the plate according to the purlin spacing to prevent the bolts from being spaced differently or not fixed on the purlin.

During the installation process, check the vertical and horizontal lap length and the joint condition of the board at any time, and adjust it in time. 1 Installation of the roof bottom plate

1.1 Introduction to the roof floor

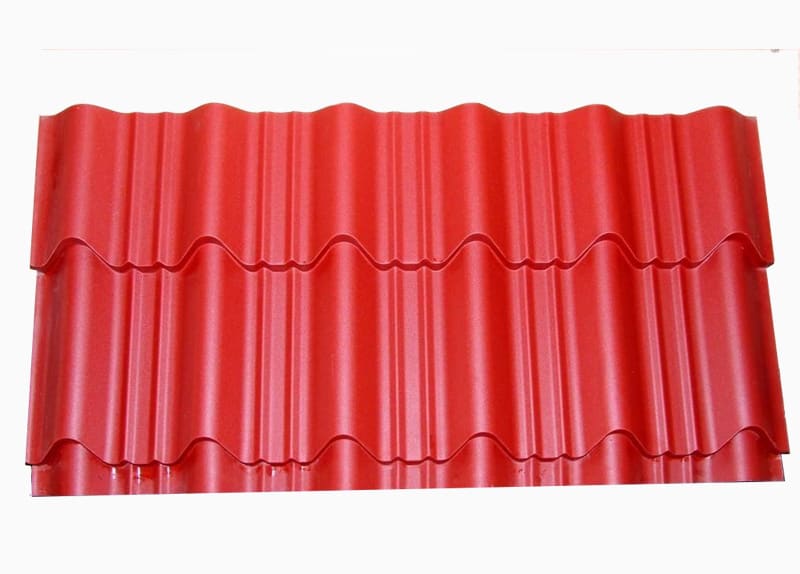

Generally, the roof bottom plate adopts 0.5mm thick galvanized steel bottom plate, and the bottom plate type adopts YX16-225-900 type. Its effective wave height is 16mm, wave distance is 225mm, and the perforation rate is generally 23%.

1.2 Measurement of roof floor control line

Before installation, the panel installation control line (roof installation parallel line) is measured on the purlin with theodolite. The straightness, deflection, and concealed project content of the purlin should be checked before the plate installation. The installation of the purlin must meet the design drawings, and the installation height of the purlin should meet the requirements to ensure the flatness of the plate after installation.

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...