- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

Handling steel coils safely and efficiently is crucial in the metal manufacturing, processing, and logistics industries. Steel coils, which can weigh several tons and come in various widths, diameters, and grades, require specific handling techniques to ensure both product quality and workplace safety. Improper handling may result in coil damage, worker injury, or equipment malfunction. This article explores the best practices for handling steel coils from a professional and practical standpoint.

1. Understanding the Nature of Steel Coils

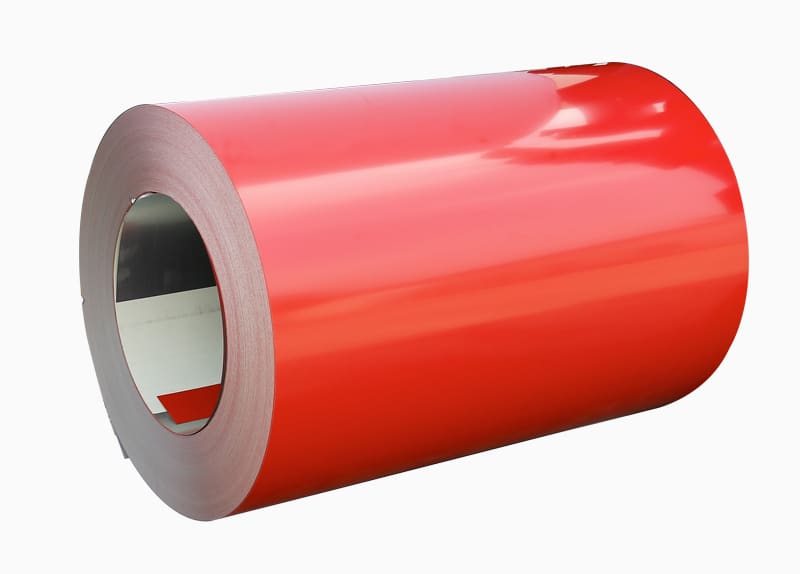

Steel coils are produced through processes such as hot-rolling, cold-rolling, or galvanizing and are typically transported in a coiled form for space efficiency. These coils can be categorized as:

Hot Rolled Coils (HRC)

Cold Rolled Coils (CRC)

Galvanized or Coated Coils

Stainless Steel Coils

Each type has its own physical and mechanical characteristics, such as surface sensitivity, edge hardness, and dimensional tolerance. These properties must be considered during handling to avoid damage.

2. Proper Equipment for Coil Handling

Using the right equipment is essential for ensuring the safe movement of coils:

a) Overhead Cranes with C-Hooks

C-Hooks are specifically designed to lift coils through their inner diameter (ID). This method is stable and minimizes surface contact, which helps prevent damage.

b) Coil Lifters and Tongs

For horizontal coils, lifters with padded or coated arms help grip the coil edges without marring the surface.

c) Forklifts with Coil Rams or Special Attachments

Standard forks may deform coils or cause unsafe shifts. Coil rams—long, cylindrical extensions—can be inserted into the ID to lift coils safely.

d) Conveyor and Roller Systems

For high-volume coil handling, automated conveyor systems can move coils efficiently between processes or stations with minimal human intervention.

3. Safe Handling Procedures

a) Pre-Inspection

Always inspect the coil, lifting equipment, and rigging before handling. Check for any deformation, rust, cracks, or foreign material on the coil.

b) Proper Rigging Techniques

Use synthetic slings or padded chains to prevent surface damage. The load should be balanced, and lifting points should be aligned with the coil's center of gravity.

c) Horizontal vs. Vertical Positioning

Vertical coils (eye to the sky) should be lifted using coil grabs or upright positioners.

Horizontal coils (eye to the side) require lifting from the inner diameter or by cradling the outer body.

d) Slow and Controlled Movements

Avoid sudden starts, stops, or jerks while lifting or moving coils. Always move the coil in a controlled and slow manner to avoid pendulum effects or tipping.

4. Storage Guidelines

Proper storage minimizes risk and maintains coil integrity.

Use coil saddles or cradles: These provide a stable surface and prevent rolling.

Stacking limitations: Avoid stacking coils unless designed for stacking. Overloading may cause deformation.

Avoid floor contact: Coils should be placed on dunnage to prevent moisture absorption and corrosion.

5. Worker Safety Measures

Personal Protective Equipment (PPE): Workers must wear gloves, safety shoes, and helmets.

Training: Employees should be trained on equipment use, load calculations, and emergency procedures.

Clear communication: Use hand signals or radios to ensure proper coordination between handlers.

6. Digital Monitoring and Automation

In modern coil handling systems, integrating automation and monitoring enhances efficiency and reduces human error:

RFID or Barcode Tracking: Helps identify and track coil specifications.

Load sensors and cameras: Enhance precision and detect anomalies.

Robotic arms or automated coil handling robots: Especially in high-throughput processing centers, automation ensures consistency and safety.

Conclusion

The best way to handle steel coils involves a combination of the right equipment, skilled workforce, safe operating procedures, and smart storage solutions. Investing in proper coil handling not only protects your inventory but also contributes to a safer workplace and more efficient operations. Companies should continually assess and update their handling systems in line with technological advancements and evolving safety standards.

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...