- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

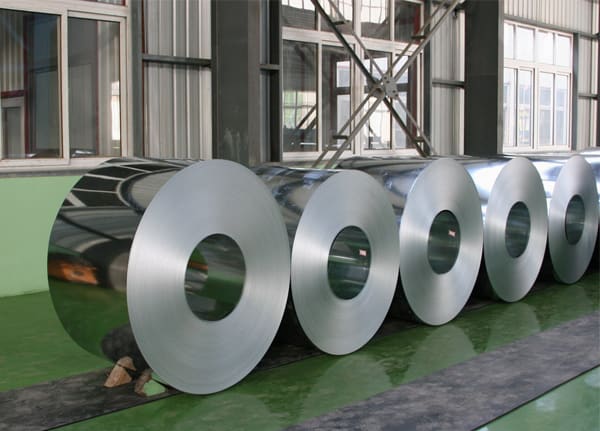

When we think of a modern heating, ventilation, and air conditioning (HVAC) system, we often focus on its ability to heat or cool a space. However, the true performance and longevity of these systems rely on a hidden hero: Hot-Dipped Galvanized Iron (HDGI) coils. These aren't just any coils; they are a critical component, providing the durability and corrosion resistance needed to keep HVAC units running smoothly for years.

At its core, a galvanized steel coil is a sheet of steel that has been submerged in a bath of molten zinc. This process, known as hot-dip galvanization, creates a metallurgical bond between the zinc and the steel. The result is a tough, durable coating that acts as a sacrificial barrier. This means that if the outer layer is scratched, the zinc corrodes first, protecting the underlying steel from rust.

For HVAC applications, this zinc-coated steel coil offers several key advantages:

Superior Corrosion Resistance: HVAC units are often exposed to moisture—from condensation in cooling coils to outdoor humidity. This constant exposure can quickly lead to rust, which compromises the structural integrity of the unit. HDGI coils are built to withstand this, preventing premature failure and reducing the need for costly repairs.

Enhanced Durability: The galvanized coil provides a hard, abrasion-resistant surface. This protection is crucial for components that may be subject to handling during installation or minor impacts over their lifespan.

Cost-Effectiveness: While the initial cost of HDGI material may be slightly higher than untreated steel, its long service life and minimal maintenance requirements result in significant long-term savings. The exceptional protection it offers means a longer operational life for the entire HVAC system.

You'll find HDGI coils, or galvanized iron coils, used in a variety of HVAC components, where their protective properties are most needed:

Ductwork: The extensive network of ducts that moves air throughout a building is a primary application. HDGI ducts resist rust from condensation, ensuring that the air delivered is clean and free from metal particles caused by corrosion.

Air Handling Units (AHUs): The casings and internal frames of these large units are often made from HDGI steel to protect them from the humid environment inside and the elements outside.

Evaporator and Condenser Coils: While the fins on these coils are often made from aluminum or copper for thermal conductivity, the structural frames and casings that house them are typically made from a zinc-coated steel coil to provide the necessary structural support and corrosion resistance.

The quality of the HDGI coil can vary depending on the zinc coating weight and the steel grade used. Manufacturers specify these details to ensure the material meets the demanding standards of the HVAC industry. For example, a coil with a heavier zinc coating will offer greater protection in highly corrosive environments, such as coastal areas.

In conclusion, the next time you enjoy the comfort of a perfectly regulated room, remember the vital role played by hot-dipped galvanized steel coils. They are the silent guardians, providing the strength and durability that allow your HVAC system to perform efficiently and reliably year after year.

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...