- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

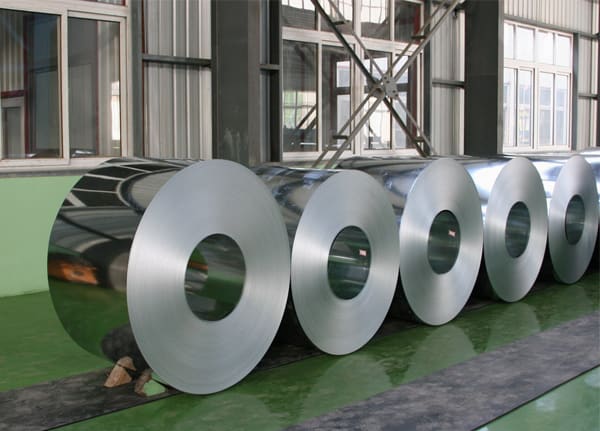

Hot-Dipped Galvanized Iron (HDGI) coils represent a cornerstone of modern industrial manufacturing, created through a rigorous process of coating cold-rolled steel with a protective layer of zinc. The process involves passing the steel through a molten bath of zinc at temperatures typically reaching 450°C. This metallurgical reaction creates a series of zinc-iron alloy layers that are molecularly bonded to the base metal. Unlike simple paint or spray coatings, the HDGI process ensures that the protective barrier becomes an integral part of the steel, providing a durable shield that can withstand mechanical stress and environmental exposure for decades.

The quality of an HDGI coil is often defined by its "spangle"—the visible crystalline patterns on the surface. Depending on the cooling rate and chemical additives in the zinc bath, manufacturers can produce regular spangle, minimized spangle, or zero spangle finishes. Each variation offers specific benefits, with zero spangle being particularly popular for applications requiring high-quality post-processing painting, as it provides a smoother, more uniform surface profile.

One of the most critical factors in selecting an HDGI coil is the coating weight, usually measured in grams per square meter (g/m²). Common standards like ASTM A653 or EN 10346 dictate the minimum requirements for various environmental conditions. A higher coating weight directly correlates with increased longevity in corrosive environments, such as coastal regions or industrial zones with high chemical exposure.

| Coating Designation | Zinc Coating Weight (Total Both Sides) | Typical Application |

| Z120 / G40 | 120 g/m² | Indoor appliances & light ducting |

| Z180 / G60 | 180 g/m² | Standard roofing & construction |

| Z275 / G90 | 275 g/m² | Heavy-duty outdoor structures |

The primary advantage of HDGI coils is their "sacrificial protection" mechanism. In the event that the steel surface is scratched or cut, the surrounding zinc coating acts as an anode and corrodes preferentially to protect the exposed steel. This cathodic protection is a unique property that sets galvanized materials apart from barrier-only coatings like powder coating or plastic lamination.

HDGI coils are highly versatile and can be subjected to various fabrication processes including bending, roll-forming, and deep drawing without the coating flaking off. This makes them the material of choice for the automotive industry, where they are used for body panels and under-chassis components. In the construction sector, HDGI coils are the primary raw material for manufacturing corrugated roofing sheets, purlins, and HVAC ductwork systems.

Furthermore, the surface of an HDGI coil is an excellent substrate for pre-painted galvanized iron (PPGI). When the coil is chemically treated and primed, it accepts architectural coatings with exceptional adhesion, allowing for the creation of aesthetically pleasing building facades that retain the structural integrity and corrosion resistance of galvanized steel. From solar panel mounting frames to agricultural silos, the HDGI coil continues to be an indispensable asset in modern engineering.

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...