- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

From warehouses to factories, the demand for durable, low-maintenance building materials continues to grow. Among the top contenders meeting this need is the PPGI corrugated steel sheet—a material that combines advanced engineering with practicality, making it indispensable across various industrial sectors.

Understanding the Technology Behind PPGI Sheets

At its core, PPGI (Pre-Painted Galvanized Iron) technology involves applying a high-quality paint coating to galvanized steel before it undergoes shaping processes. This preemptive treatment ensures uniform coverage and adhesion, resulting in a product that resists chipping, peeling, and fading far better than post-painted options. The corrugation process adds ridges to the surface, enhancing the sheet's load-bearing capacity and rigidity without adding significant weight.

Key Advantages for Industrial Use

For industrial applications, performance under pressure is paramount—and PPGi corrugated steel sheets deliver. Their robust construction allows them to endure heavy machinery vibrations, frequent foot traffic, and exposure to chemicals or moisture. These qualities make them particularly well-suited for environments such as manufacturing plants, storage facilities, and processing units.

Moreover, the pre-painted finish offers more than just visual enhancement; it acts as a shield against oxidation and degradation caused by humidity, salt spray, and pollutants. For industries located near coastal areas or in regions with challenging climates, this added layer of protection translates into reduced maintenance costs and prolonged service life.

Cost-Effectiveness Without Compromise

One of the standout features of PPGI corrugated steel sheets is their affordability. While initial costs may be slightly higher than those of unpainted galvanized sheets, the long-term savings are substantial. The extended lifespan and minimal upkeep requirements mean businesses spend less on repairs, replacements, and downtime. Furthermore, the ease of installation cuts down on labor expenses, allowing projects to be completed faster and within budget.

Customization Meets Functionality

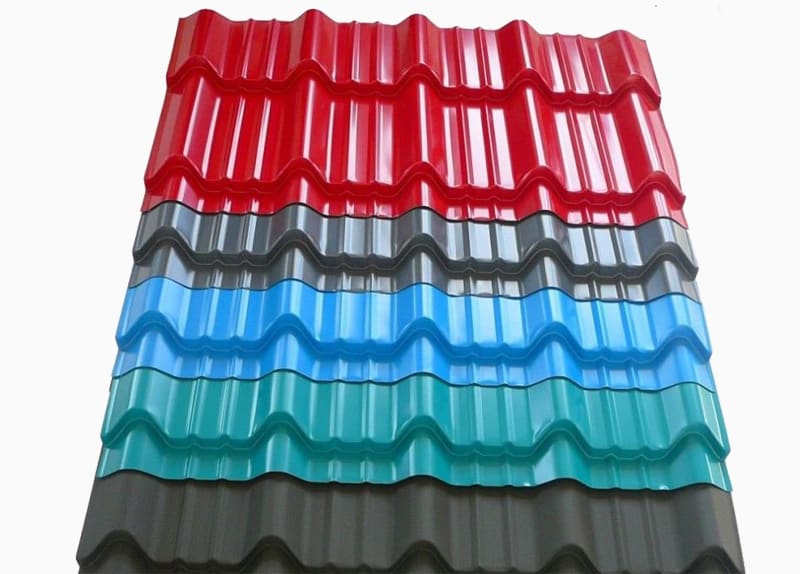

Beyond their mechanical advantages, PPGI sheets provide ample opportunities for customization. Available in a spectrum of colors and textures, they enable companies to align their infrastructure with branding guidelines or specific aesthetic preferences. For instance, food processing plants might opt for clean, white panels to maintain a hygienic appearance, while automotive workshops could choose bold hues to create a dynamic workspace environment.

Contributing to Sustainable Practices

Industrial operations are increasingly expected to adopt sustainable practices, and PPGI corrugated steel sheets align perfectly with this goal. Many manufacturers now produce these sheets using recyclable materials and energy-efficient production methods. Once installed, their reflective properties can help reduce cooling costs during summer months, contributing to overall energy savings.

Additionally, because PPGI sheets are so durable, they contribute to resource conservation by minimizing the frequency of replacements. When the time does come for disposal, the metal can be fully recycled, closing the loop on its lifecycle.

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...