What are the main functions of galvanized coil in life

Update:02,Feb,2023

Summary: One of the new materials of galvanized coil, its main raw material is zinc alloy, and the production process of galvaniz...

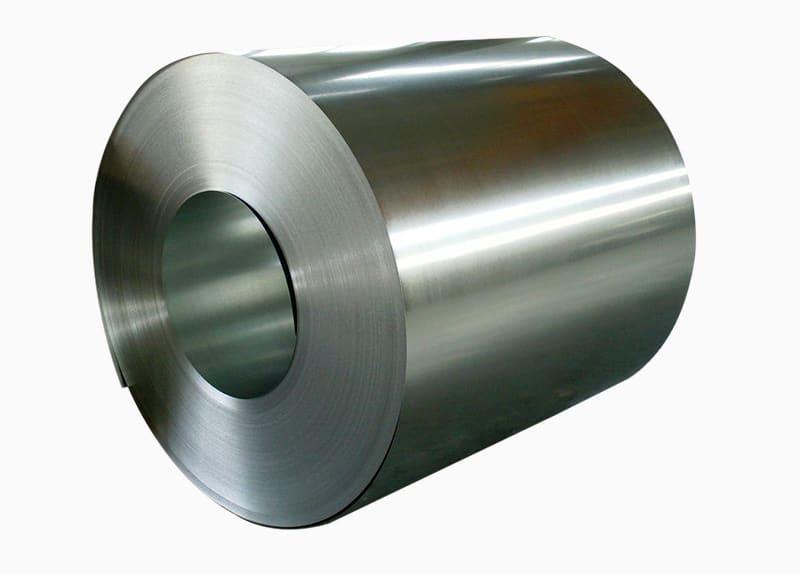

One of the new materials of galvanized coil, its main raw material is zinc alloy, and the production process of galvanized coil is continuous galvanizing.

There are many types of galvanized coils. We mainly classify them according to their performance. We usually use numbers. Galvanized coil is still very popular in the world today. Its advantages are good adhesion and weldability. Similarly, nothing in the world is faultless, and so is the galvanized coil. Its disadvantages include exposed steel, inclusion, mechanical damage, etc., which is mainly caused by surface oxidation.

Main application industries of galvanized coil:

A large number of galvanized thin coils are used in automobile manufacturing, cold box, construction, ventilation and heating facilities, furniture manufacturing and other fields. Zinc plating has become an important method of steel corrosion prevention, not only because zinc can form a dense protective layer on the steel surface, but also because zinc has the cathodic protection effect. When the zinc coating is damaged, it can still prevent the corrosion of ferrous base metal through the cathodic protection effect.

Construction industry: roof, roof components, balcony surface rolls, window sills, newspaper kiosks, warehouses, rolling shutter doors, heaters, rainwater pipes, etc.

Household appliances: refrigerator, washing machine, switch cabinet, air conditioner, microwave oven, bread maker, copier, vending machine, electric fan, vacuum cleaner, etc.

Furniture industry: lampshade, wardrobe, table, bookshelf, counter, signboard, medical equipment, etc.

Transportation industry: car ceiling roll, car shell, carriage roll, tractor, tram, container, highway fence, ship compartment roll, etc.

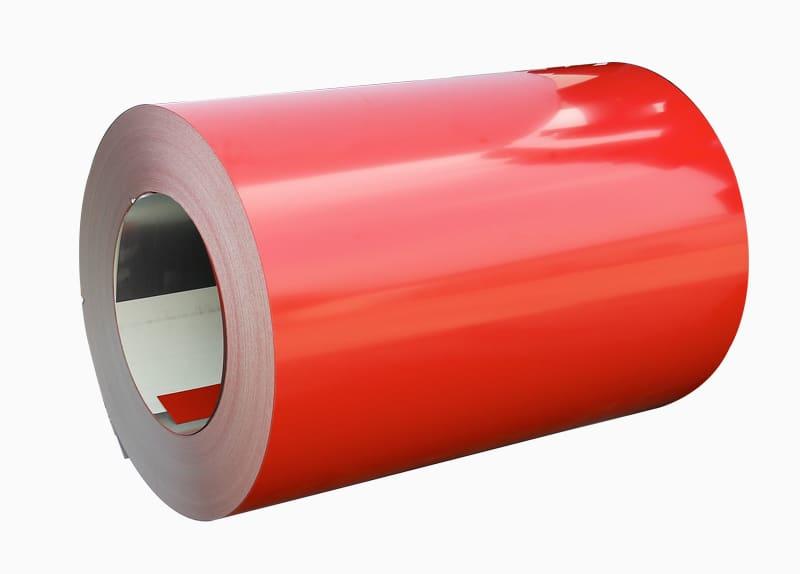

Other aspects: The colored coated steel coils, such as musical instrument shell, dustbin, billboard, clock, camera equipment, and meter, are based on hot-dip galvanized coils, hot-dip aluminum-zinc coils, and electro-galvanized coils, and are subject to surface pretreatment.

Of course, when making galvanized coils, passivation treatment must be carried out before the second step of oil coating can be carried out, and then paint sealing and phosphating can be carried out. The galvanized coil produced after a long process is very durable. Of course, if the user does not need phosphating, this process can be omitted during the production process! When using the galvanized roll, we must prevent scratches, because the galvanized roll has no effect of preventing friction, otherwise the galvanized roll will be damaged by your carelessness.