- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

The substrate of the color-coated plate can be divided into cold-rolled substrate, hot-dip galvanized substrate, and electro-galvanized substrate.

The coating types of color-coated panels can be divided into: polyester, silicon modified polyester, vinylidene fluoride, and plastisol.

The color of the color-coated board can be divided into many types according to user requirements, such as orange, cream, deep sky blue, sea blue, crimson, brick red, ivory, porcelain blue, etc.

The surface condition of color-coated plates can be divided into coated plates, embossed plates, and printed plates.

The use of color-coated sheets in the market is mainly divided into three parts: construction, home appliances and transportation. The construction sector accounts for the largest proportion, followed by the home appliance industry, and the transportation industry accounts for only a small part.

Color-coated sheets for construction generally use hot-dip galvanized steel sheets and hot-dip galvanized steel sheets as substrates, which are mainly processed into corrugated sheets or composite sandwich panels with polyurethane, which are used to construct steel structure factories, airports, warehouses, freezers and other industries and Roofs, walls and doors of commercial buildings.

Home appliance color plates generally use electro-galvanized and cold plates as substrates, which are used to produce refrigerators and large air-conditioning systems, freezers, bread machines, and furniture.

In the transportation industry, electro-galvanized and cold plates are generally used as substrates, which are mainly used for oil pans and automotive interior parts.

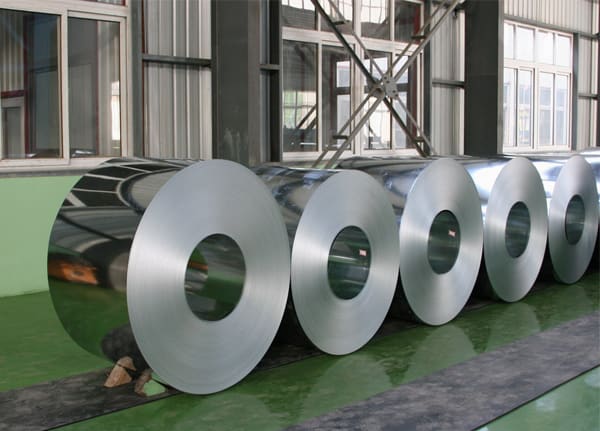

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...