Summary:

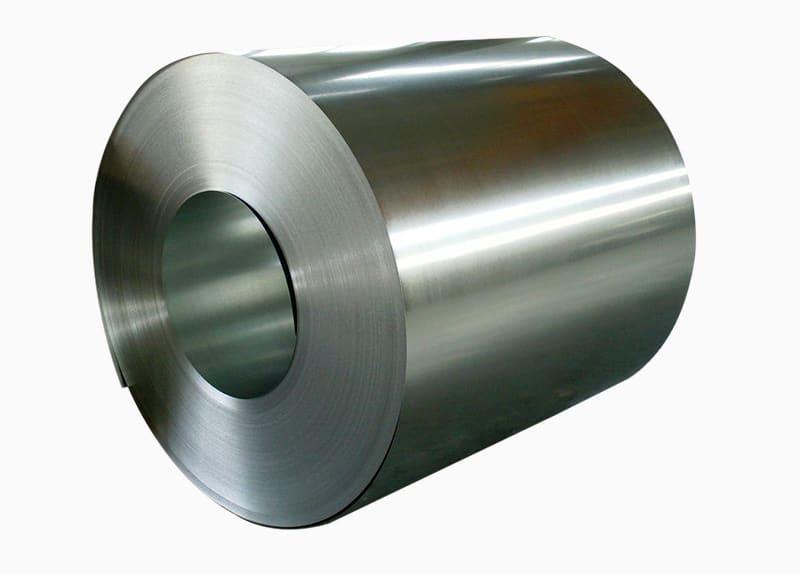

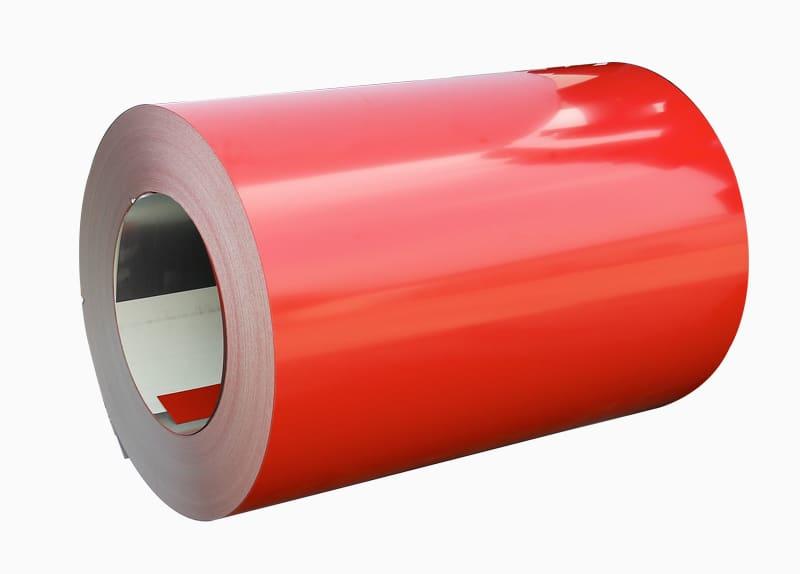

Color-coated roll, a kind of magical building material, is deeply loved by people because of its high efficiency, energ...

Color-coated roll, a kind of magical building material, is deeply loved by people because of its high efficiency, energy saving and environmental protection characteristics. What are the advantages of the color coated roll production line? Let's take a look together!

(1) The production line is designed with high-performance special coil coatings and process routes. It can automatically and continuously complete the processes of uncoiling, degreasing cleaning, chemical conversion treatment, roller coating, curing, cooling and coiling, which truly embodies the automation and high speed of color coating. The coating film adhesion, hardness and anti-aging properties can reach the ideal technical performance of the coating and the actual use requirements of users.

(2) Adopting advanced infrared or hot air circulation continuous drying equipment, the temperature of each section in the drying furnace can be automatically adjusted, which has the characteristics of high thermal efficiency and low energy consumption. In order to ensure the process temperature when the steel strip passes, the goal of good appearance quality of the coating film and fast curing speed is achieved.

(3) The entire line of equipment is equipped with explosion-proof safety protection facilities, and advanced automatic program control makes the entire production process orderly, efficient, safe and reliable.

(4) It can be flexibly configured with post-coating processing equipment such as laminating, embossing, printing, peelable film and wax spraying. These devices can not only meet the diversified needs of color-coated products, but also provide for the forming and processing of color-coated rolls. Surface protection to prevent bending, cutting, and scratching.