Summary: Metal panel and non-metal panel. Metal panels are easy to process and can be made into various shapes, but in some cases...

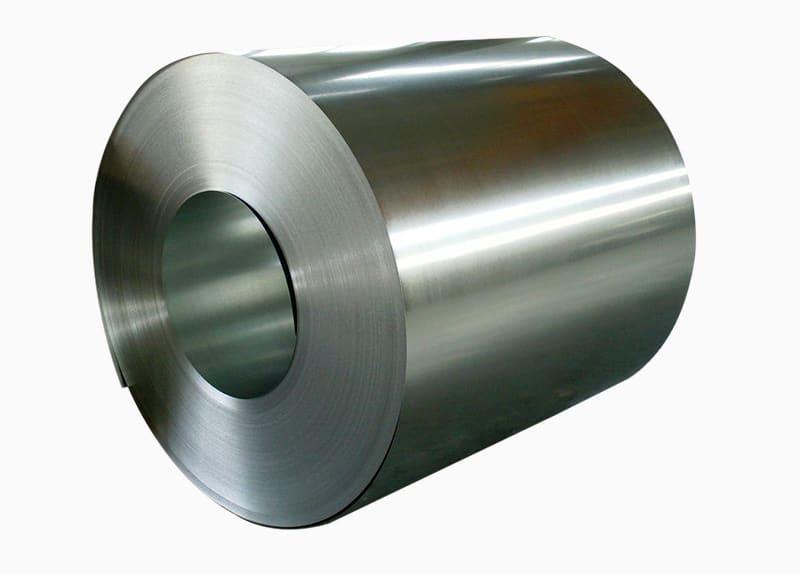

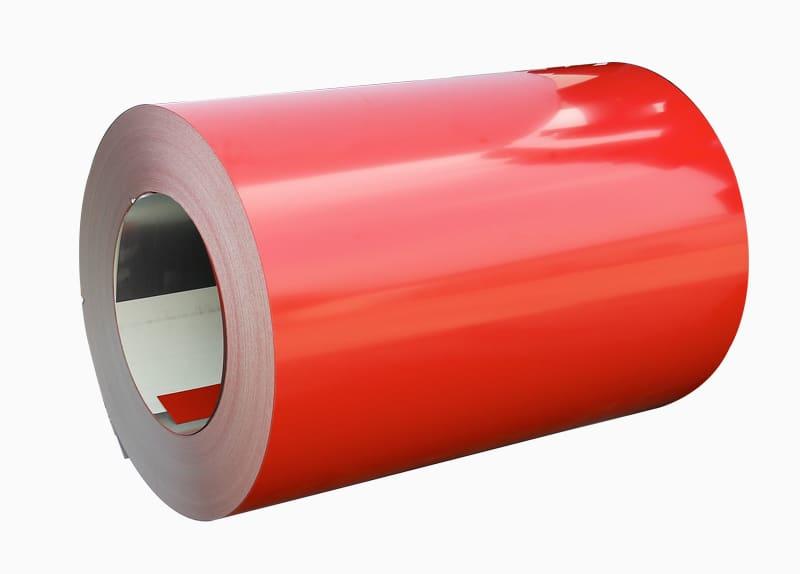

Metal panel and non-metal panel. Metal panels are easy to process and can be made into various shapes, but in some cases, non-metal panels have functions that metal panels cannot, such as corrosion resistance and impact resistance.

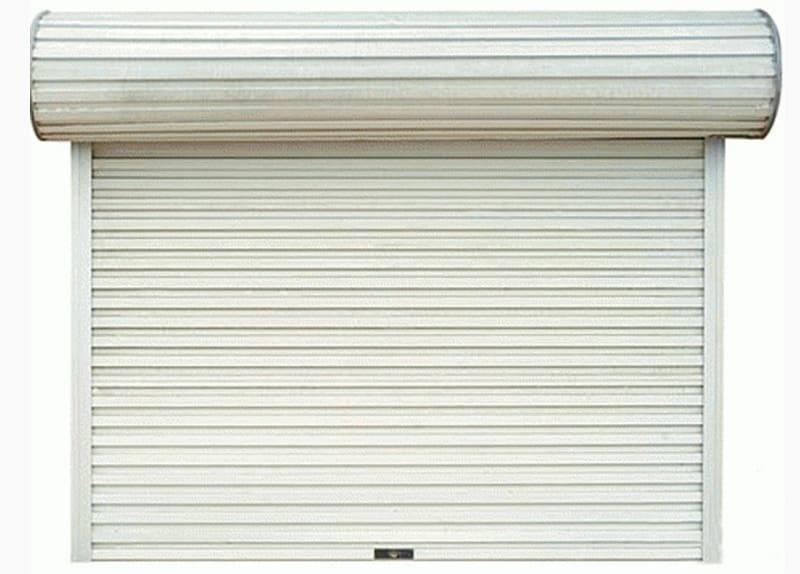

It is widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storages, mobile rooms, building layers, clean workshops and places that require thermal insulation and fire prevention. The sandwich panel is beautiful in appearance, bright in color and good in overall effect. It integrates load-bearing, heat preservation, fire prevention and waterproofing, and does not require secondary decoration. It is fast and convenient to install, has short construction period and good comprehensive benefits. It is a widely used, extremely Potential high-efficiency and environmentally friendly building materials.

The

color steel sheet sandwich panel not only has the properties of high mechanical strength and easy forming of steel materials, but also has good decoration and corrosion resistance of coating materials. Color steel sandwich panel is an emerging material respected in the world today. With the advancement of science and technology, the enhancement of environmental awareness, and the improvement of people's living standards, color steel sandwich panel prefab houses are increasingly showing strong vitality and broad market prospects. , office equipment and other industries of all ages.

The cores used in color steel sandwich panels mainly include phenolic foam, polyphenylene, extruded polystyrene, rigid polyurethane, tri-polyester and rock wool, etc., and phenolic foam has excellent fireproof and thermal insulation properties, which cannot be replaced by other materials. For example, the thermal insulation effect of phenolic foam is more than twice that of polystyrene, and its fire resistance is also higher than that of polyurethane. When polyurethane is burned, it will release heavy smoke containing hydrogen cyanide.

With the country's emphasis on building fire protection and the introduction of relevant laws, it is believed that phenolic color steel sandwich panels will create a blue sky in the field of construction.

Color steel plate can be fireproof from six aspects: First, rock wool with good fireproof performance is used as the core material, which is a cure for the root cause. 2. During the construction process, the core material should be kept away from open flames such as electric welding and gas welding; If you want to set up a kitchen in the color steel plate room, you need to have a thermal insulation layer, and the wall should be equipped with a fire-resistant rock wool thermal insulation layer; Fourth, the wires and cables should not pass through the core material. Sockets and switch boxes should be made of metal galvanized boxes and installed in the open; 5. Simple fire-fighting equipment should be provided indoors and outdoors, and fire alarms should be installed if conditions permit to facilitate rapid evacuation of personnel; 6 meters safe distance. Although the sandwich filling material of color steel plate room without strict flame retardant treatment is flammable, it will not spontaneously ignite. Strict, scientific and effective management to keep the fire away from the flammable color steel house sandwich filling material is one of the important ways to prevent fire in the color steel house.