Briefly analyze the specifications and performance of color steel sandwich panels

Update:25,Mar,2022

Summary: 1. The color steel sandwich panel is often of the tongue-and-groove plug-in type. It has the advantages of convenient in...

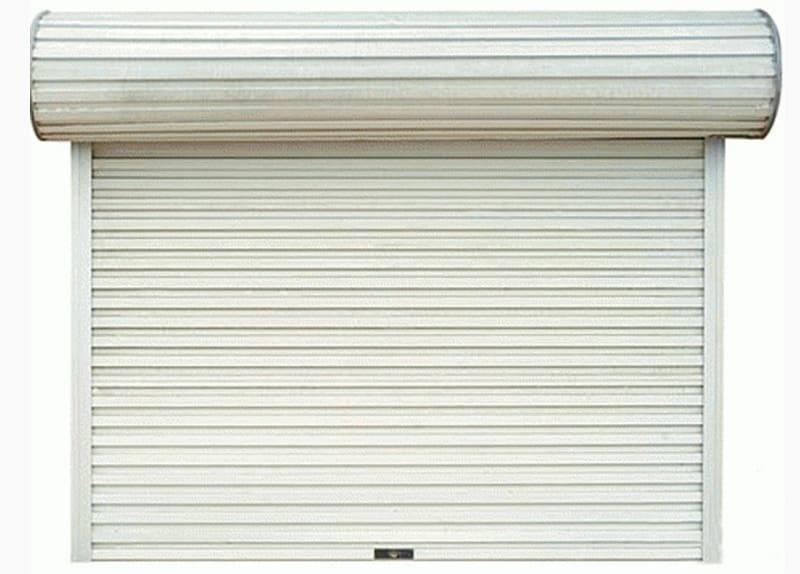

1. The color steel sandwich panel is often of the tongue-and-groove plug-in type. It has the advantages of convenient installation, time saving, material saving, good flatness and high strength, and is especially suitable for suspended ceilings and partition systems.

2. Thickness (mm): 50-250;

3. Length (mm): Due to continuous molding production, the length of the board can be determined according to user needs;

4. Width (mm): 1150 (1200) ( 960) (950)

5. Core material properties: A. Polystyrene Bulk density: ≥15kg/m3 Thermal conductivity ≤0.036W/m.K High operating temperature: about 100 oC

B. Rock wool Bulk density: ≥120kg/m3 Thermal conductivity: ≤0.043W/m.K High operating temperature: about 500 oC A|Incombustibility: B1 grade B, Incombustibility: A grade

A. The 950 corrugated color steel sandwich panel integrates the corrugated board and the sandwich panel, and the strength is increased by three times compared with the ordinary flat color steel sandwich panel. The hidden self-drilling screws are used to connect with the roof truss, which does not damage the exposed color-coated panels. part, prolong the life of the color steel sandwich panel; the connection between the panel and the panel adopts the button cap type, which is convenient for construction and improves the efficiency, and is not easy to seep water.

B. Rock wool thermal insulation color steel sandwich panel The core material is made of basalt and other natural ores as the main raw materials, which are melted into fibers at high temperature, added with an appropriate amount of binder, and cured and processed. This product is suitable for thermal insulation and sound insulation of industrial equipment, buildings, ships, etc. It is also suitable for ceilings and partitions in clean rooms, explosion-proof and fireproof workshops, etc.

C. PU polyurethane color steel sandwich panel The bonding strength of the sandwich panel is not less than 0.09MPa, the combustion performance of the sandwich panel reaches the B1 level, and the bending bearing capacity The deflection of the sandwich panel is Lo/200 (Lo is the distance between the supports) When the flexural bearing capacity of the sandwich panel is not less than 0.5Kn/m2

thermal insulation

The commonly used thermal insulation materials of the color steel plate composite board are: rock wool, glass fiber wool, polystyrene (EPS), polyurethane, etc., with low thermal conductivity, so that the prefab house, integrated house, steel structure workshop, etc. have good thermal insulation effect. High-strength color steel plate uses high-strength steel plate as the base material (tensile strength 5600kg/cm) plus advanced design and roll forming. Therefore, the color steel prefab house has better structural characteristics.