- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

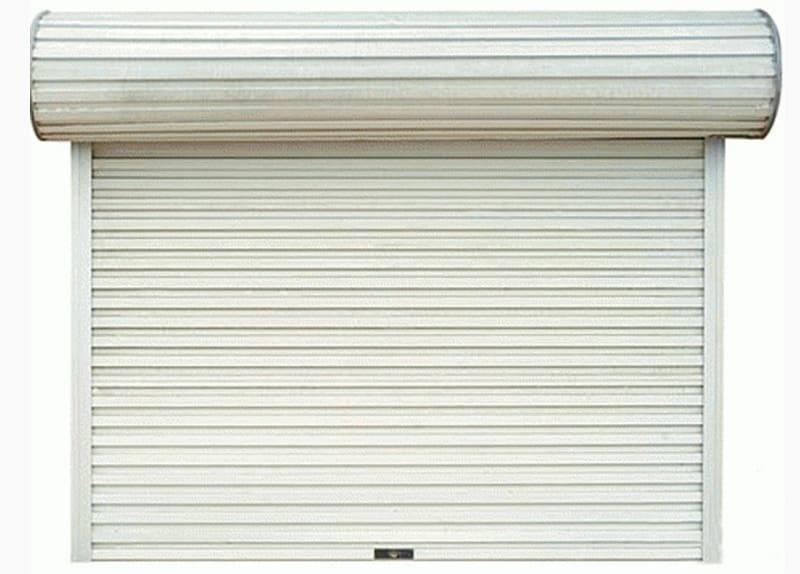

The rock wool purification color steel plate adopts medium and high density rock wool as the core material, and the galvanized or color coated plate is the surface layer and the high-strength adhesive agent is heated and pressurized by the high-speed continuous automatic molding machine to be trimmed, slotted and unloaded.

A new generation of architectural and decorative panels.The application range of rock wool purification color steel plate is very wide, and there are many applications in the industry:

Industry: Industrial workshops have a large impact on the noise of the surrounding environment.

The use of color steel sheet can eliminate noise by more than 70%.Warehouse, cold storage: The goods in the warehouse are sensitive to temperature. Using rock wool to clean color steel plates to build a warehouse can keep the temperature in the warehouse at a constant temperature, thus protecting the goods; most of the goods are flammable materials, rock wool purification color steel plate can Effectively isolates the flame from erosion and can last up to 90 minutes, minimizing economic losses.

ABOUT US

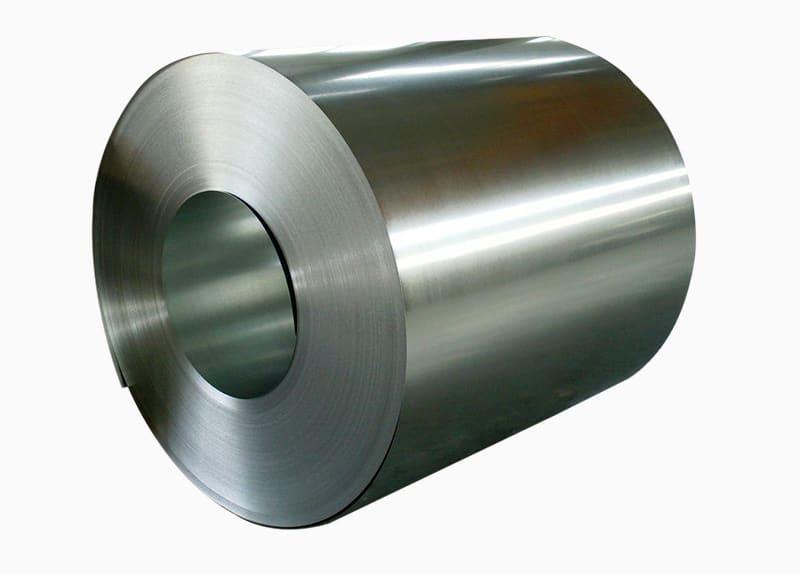

With high anti-rust performance, they are popular used in co...

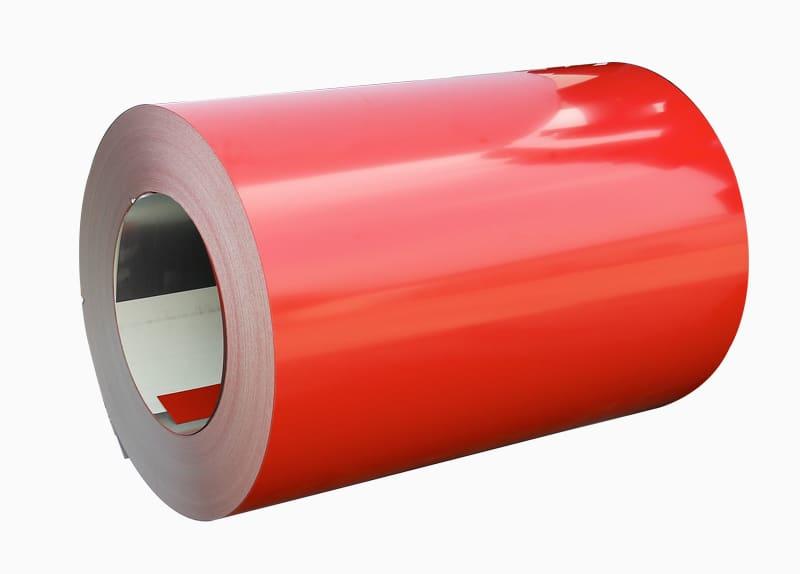

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...