- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

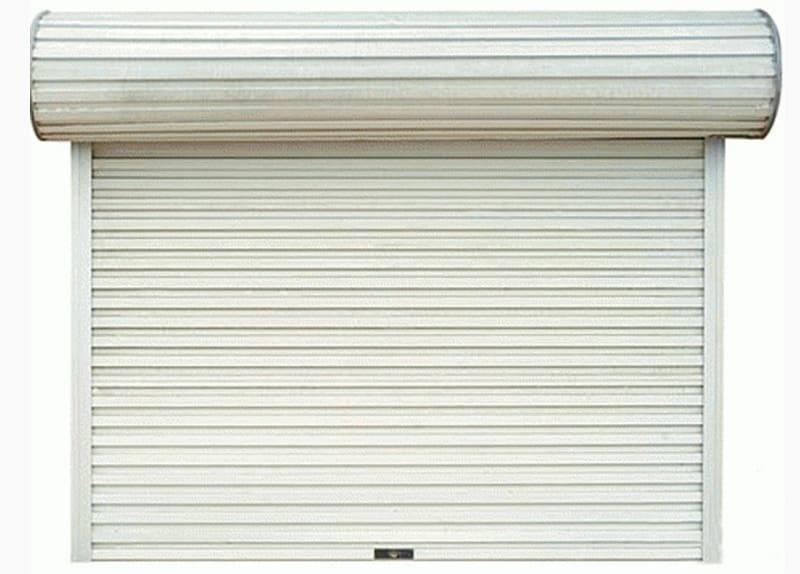

Color steel tile in the installation process, if the construction can be carried out smoothly, and the late use of good results, then the construction process should pay attention to some problems. In the process of building, color steel tile core material away from welding, gas welding and other fire operations. In the use of color steel tiles, some heat, the fire source should not be next to the color steel tile, to maintain a certain distance. The installation process should pay attention to the correct way to tile. The overlap is suitable for roofs with a length of ≦ 15M, while the staggered type is suitable for roofs with a length of ≧ 15M.

Special nails must play in the middle of the tile in order to have a waterproof effect. Install the seal when the seal is divided into two halves, the installation process to highlight some of the water treatment. The final tilt surface installation should pay attention to the installation of water under the tile material, and then use waterproof adhesive or cement to do finishing treatment.

1, color steel tile installation workers need to be certified professionals.

2, the skeleton must be installed firmly.

3, the installation must be walking in the tile, try to step on the middle of the tile, to avoid stepping on the edge of the tile.

4, harsh weather should be carefully installed.

The universal application of color steel tile, making our architectural appearance more colorful, beautiful and tidy. In the installation, the tapping screw drilling, hand, sawing or other operations will be in the roof or adjacent areas to stay in metal scraps, these things must be timely from the roof, water board, gutter, etc. clean, To be free solid debris oxidation surface lead to the formation of stains on the surface of the color plate, resulting in corrosion of steel.

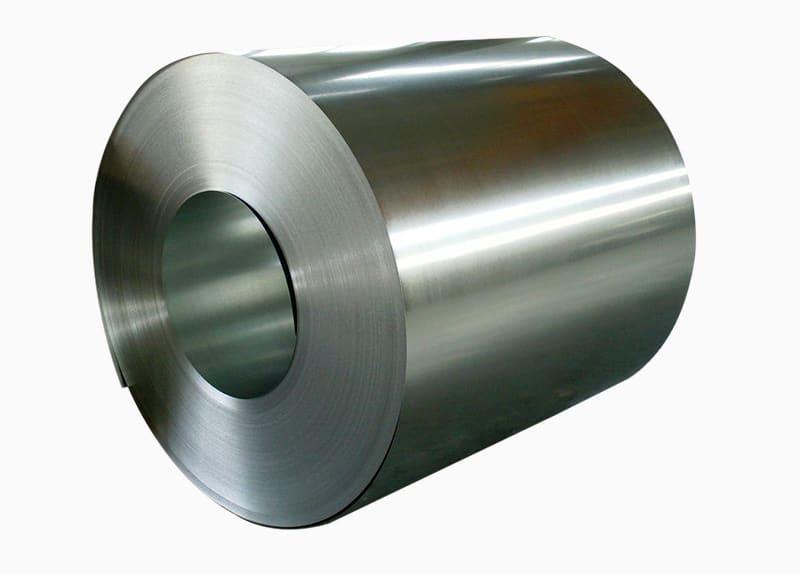

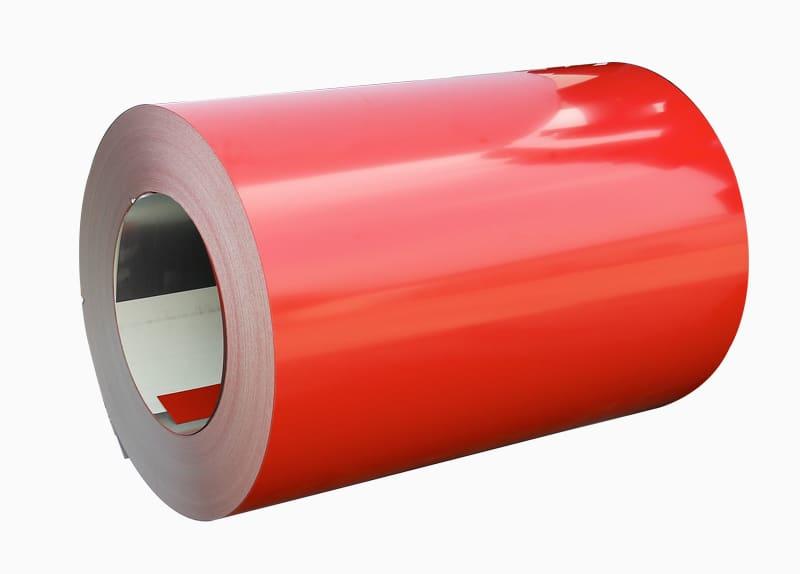

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...