- no.8,zaolin road,

longxiang street,

tongxiang,zhejiang,china - +86 573 89381086[email protected]

- DownloadsPDF Brochures

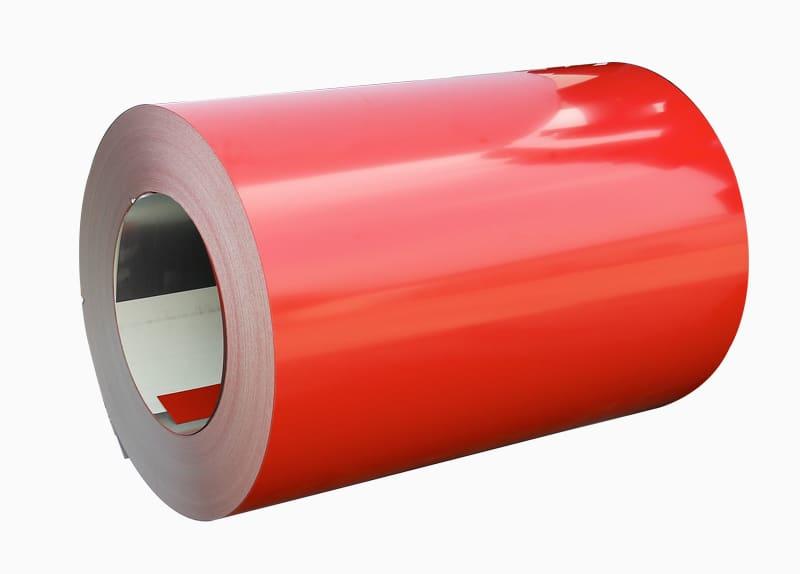

The most important step of the printing plate is color coating printing. The result of color coating will determine the quality of the finished product. So the manufacturer is doing this step carefully and carefully according to the steps to complete the production.

The following steps are included:

Methods / steps

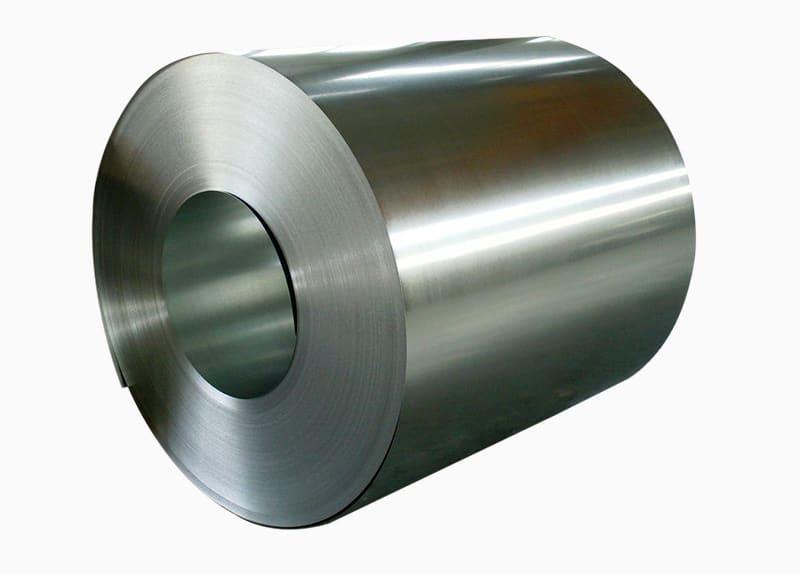

First, the rolled steel plate is pre - degreased, rolled and skimmed, and then the steel plate is cleaned.

Then the outside surface of the steel plate after cleaning is lapping until the surface of the steel plate is smooth, and then the steel plate is made and cleaned.

Coating, drying, bottom coating, coating the back paint on the bottom, and cooling the steel plate.

The steel plate after cooling is painted and painted, and then the paint is solidified with the adjustable blow nozzle device. After that, the finished printing plate is finished, and the curing time is 20-30 seconds.

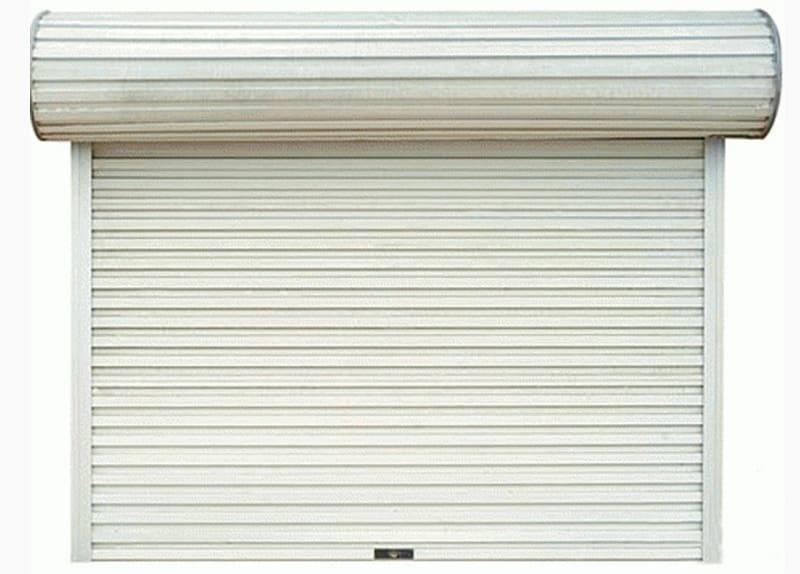

With high anti-rust performance, they are popular used in co...

PPGI / PPGL COIL full name is prepainted galvanized / galval...

Port:Zhejiang,China Advantages of Our Prepainted Galvanized ...

APPLICATION OF PPGI Construction:Outside:Workshop, agricultu...